The new Inventory feature in VendingMetrics lets you control the inventory both in your warehouse and in each vending machine. Save the paper and keep all product changes, orders, ins, and outs online, in one system!

Inventory — your virtual warehouse

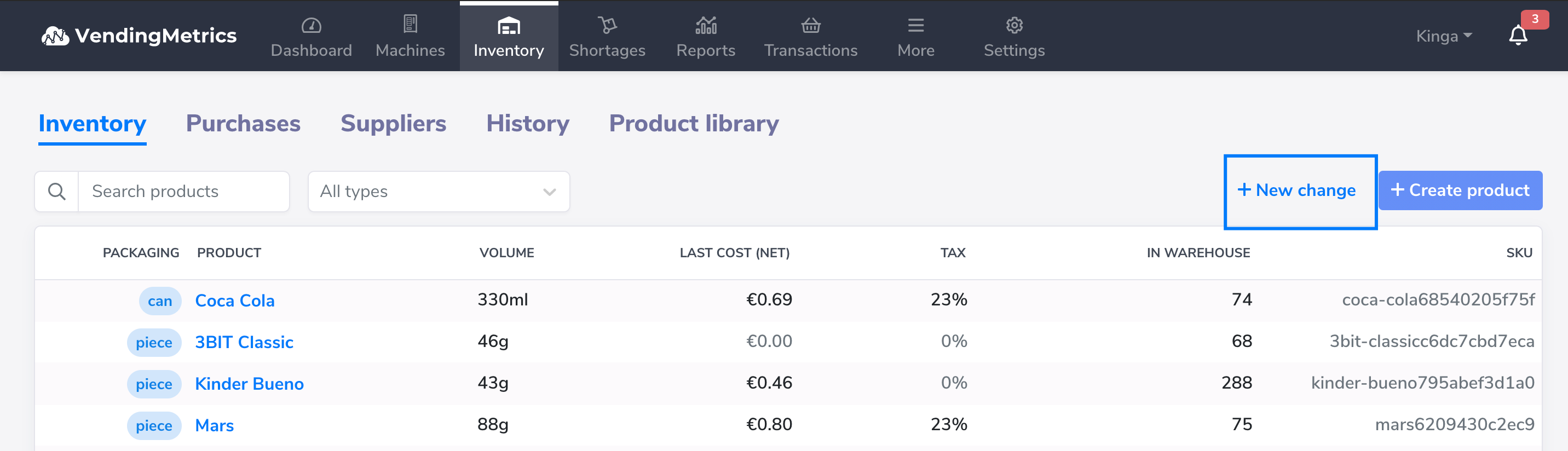

In the Inventory tab, you will find all your products that are stored in your warehouse or assigned to vending machines slots. To create new products or add products from the library, check our guide on product configuration here.

Thanks to the inventory management, you can control product stock in one place and avoid sudden issues like running out of stock. Start with adding current product quantity in your warehouse to keep the inventory up to date!

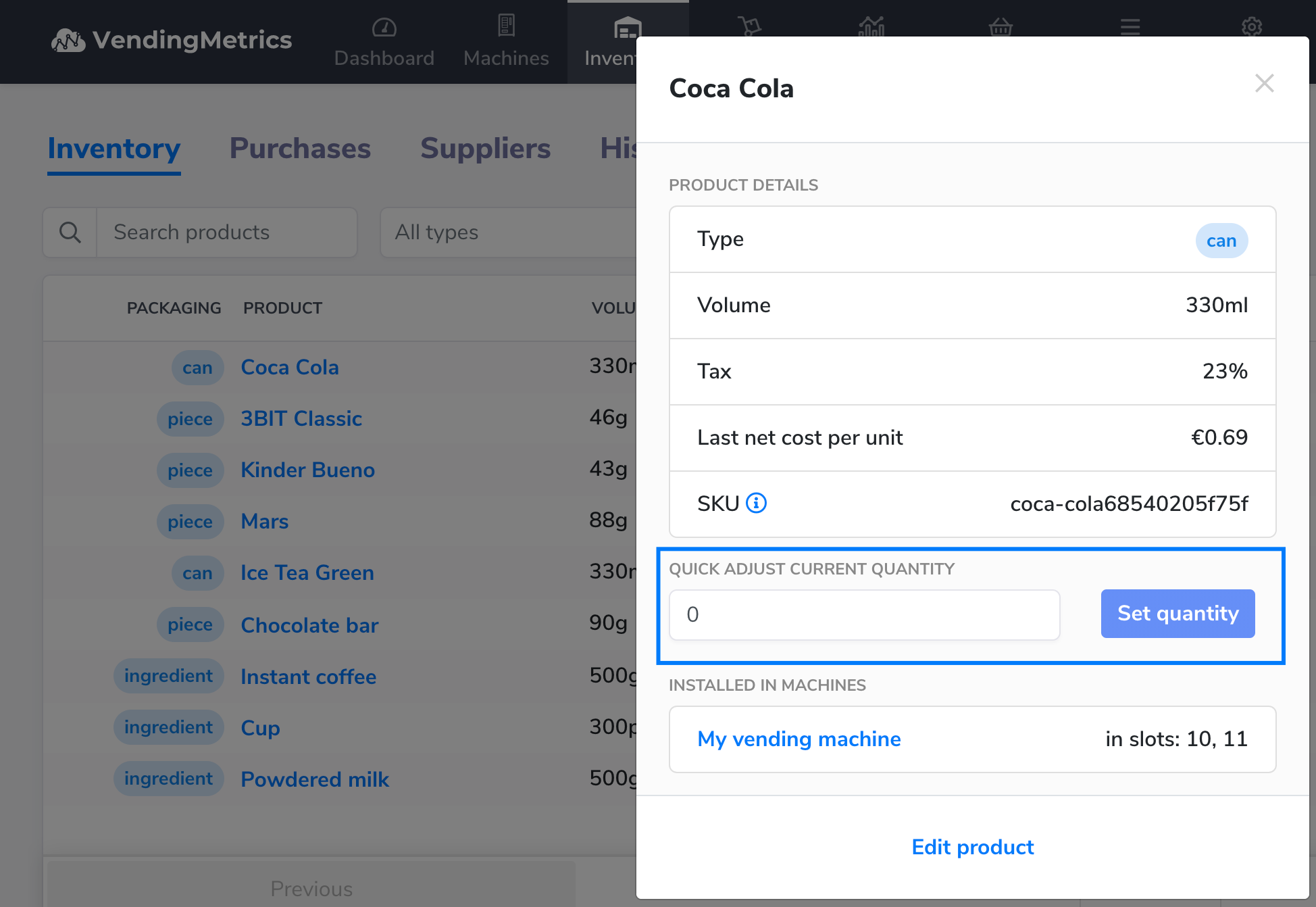

To do that, go to Inventory and select the product you want to adjust. The Edit Product window will appear and there you can click on Set current quantity button to adjust the product in your warehouse. Enter the value and save the changes.

Register all Inventory changes

Register all changes in the inventory, like picking list, product loss and other adjustments to keep the inventory level up to date.

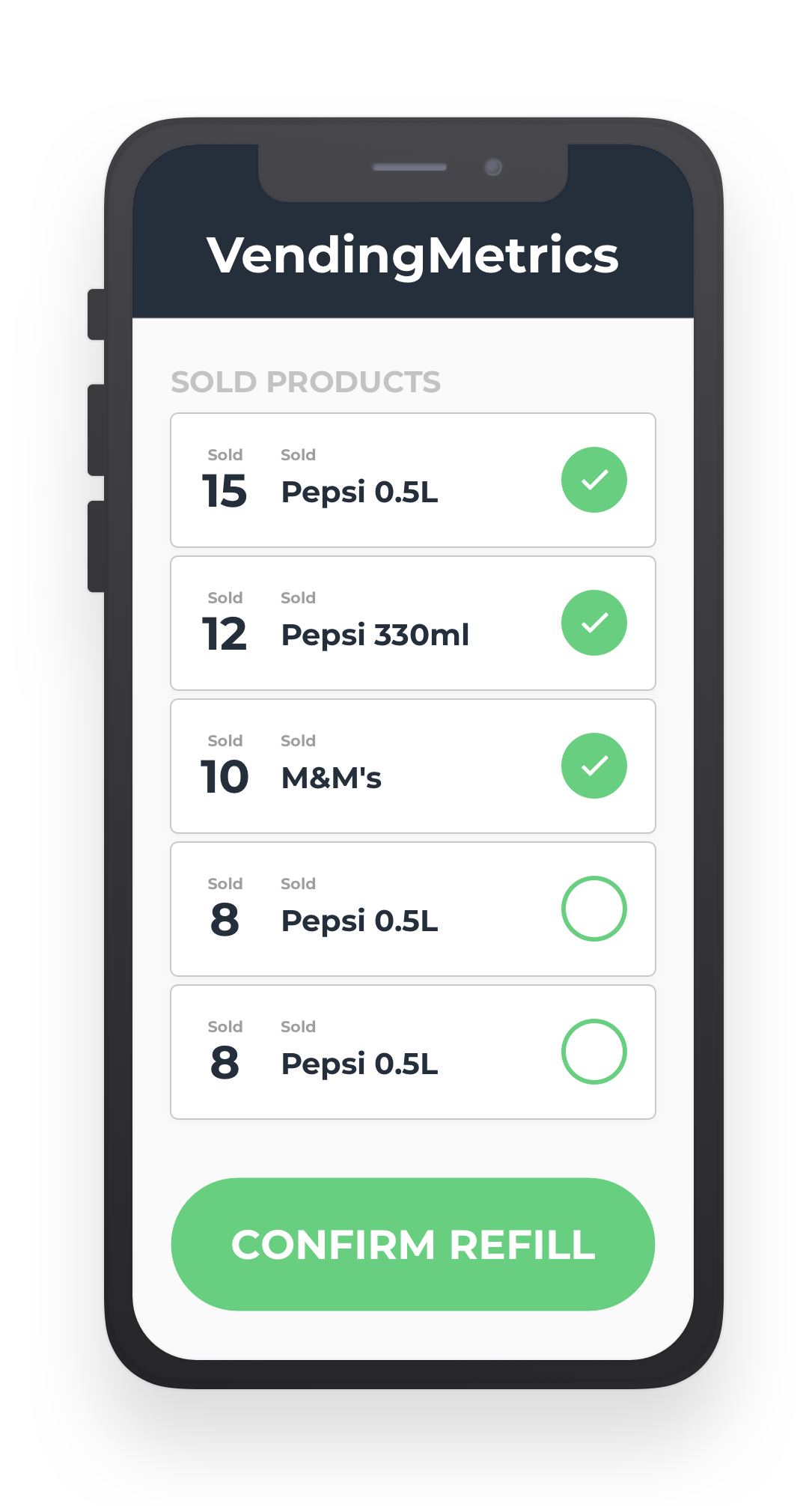

Pick products

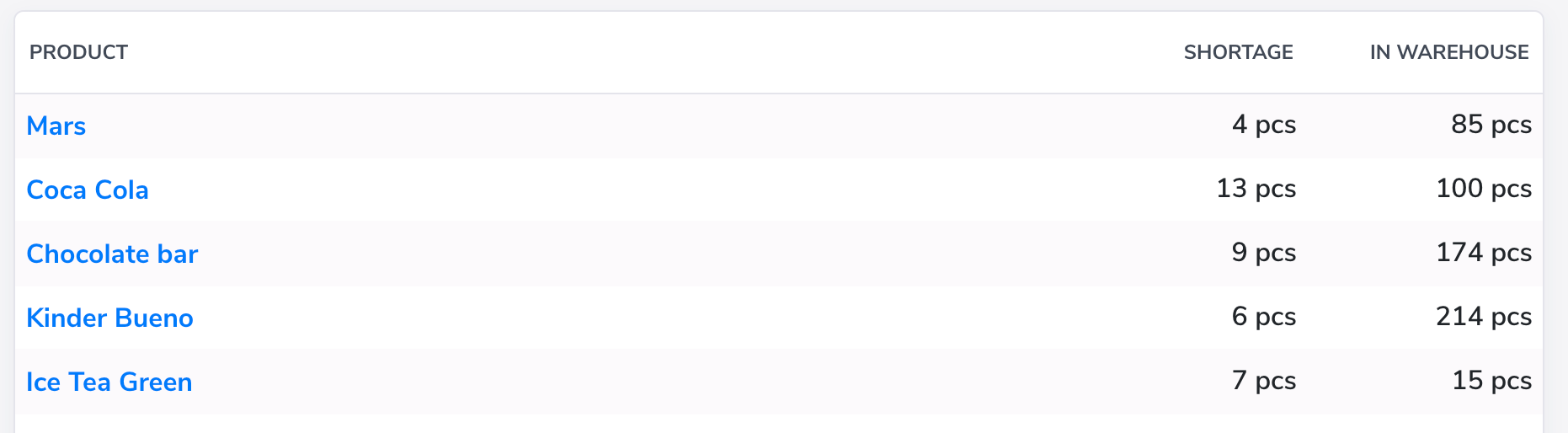

When you pick up your products to restock your machines, in Shortages tab you can check the list of all missing products and their inventory level in your warehouse:

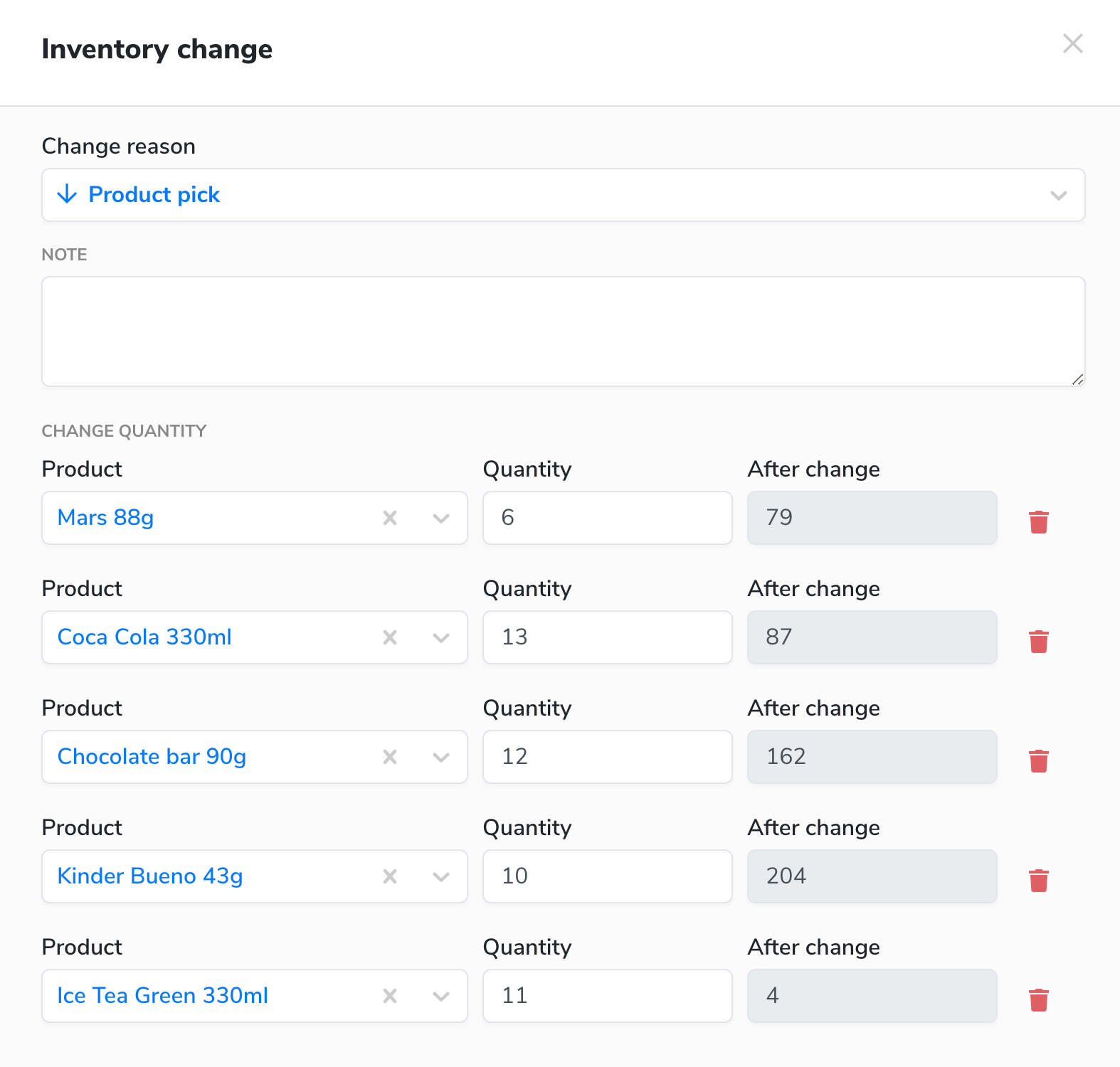

When picking up the products from the warehouse, use the Pick products button on the web or mobile app to mark how many products you are taking from the inventory. By default, the system will show you the current shortage for each item, but adjust it according to the quantities you take from the warehouse.

Thanks to this feature, you can control how many products go out from the warehouse and how many of them are really restocked in your machines. That's a great monitoring option for product and sale looses.

Product entries and exits from the inventory

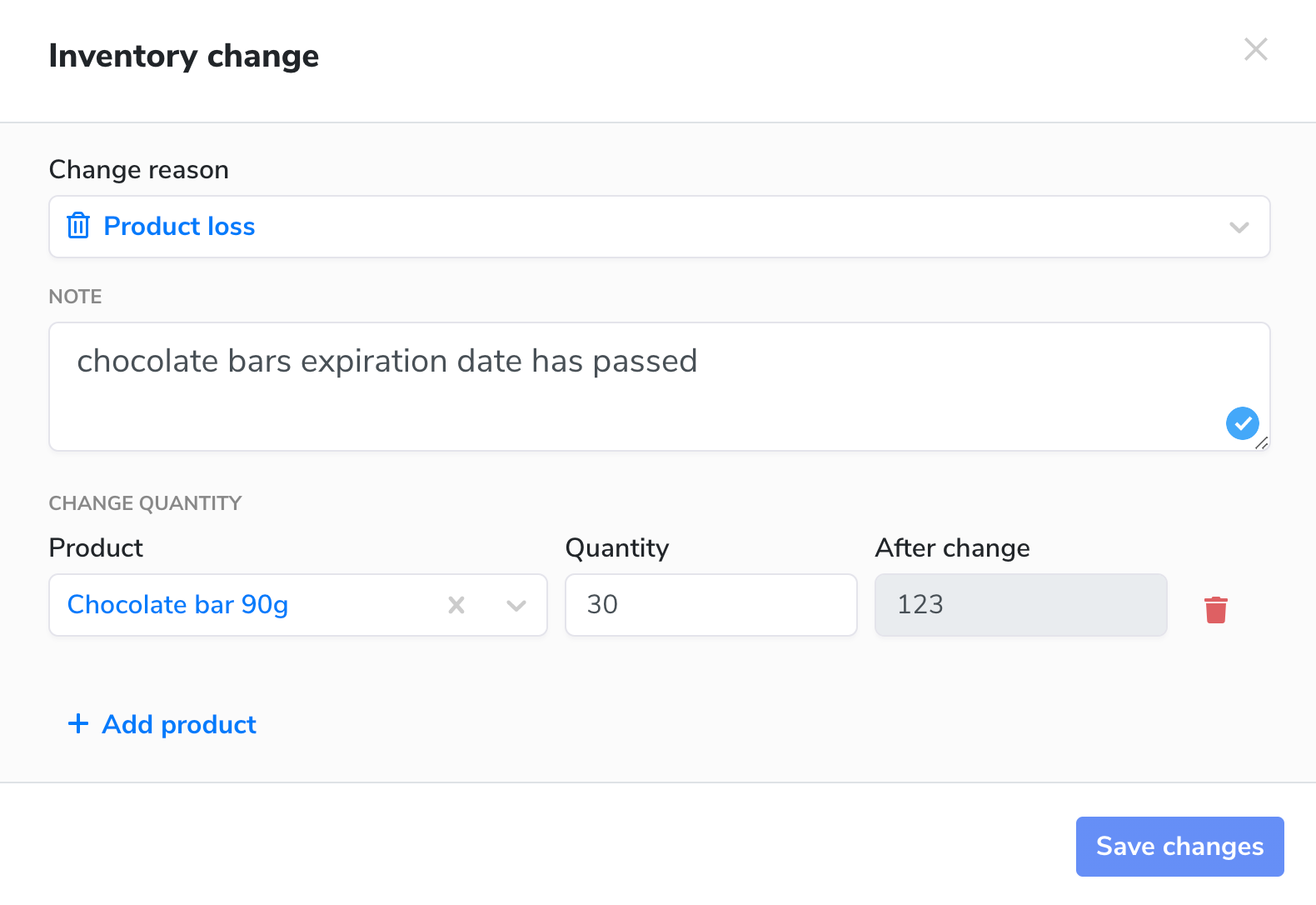

In the Inventory tab, you can register all product entries and the actions when products are leaving the warehouse. To add such change, click on New change option:

There, select the change reason: Product receive — when product enters the warehouse

- Product pick — when product leaves the magazine

- Product loss — when you lose the product, e.g., it passes the expiry date, or it gets lost

- Set new quantity — when you want to set up the current product quantity at start

- Adjust quantity — adjustment to register a mistake or other changes in product inventory

Enter the new quantity or the adjustment and save the changes.

Purchases and orders

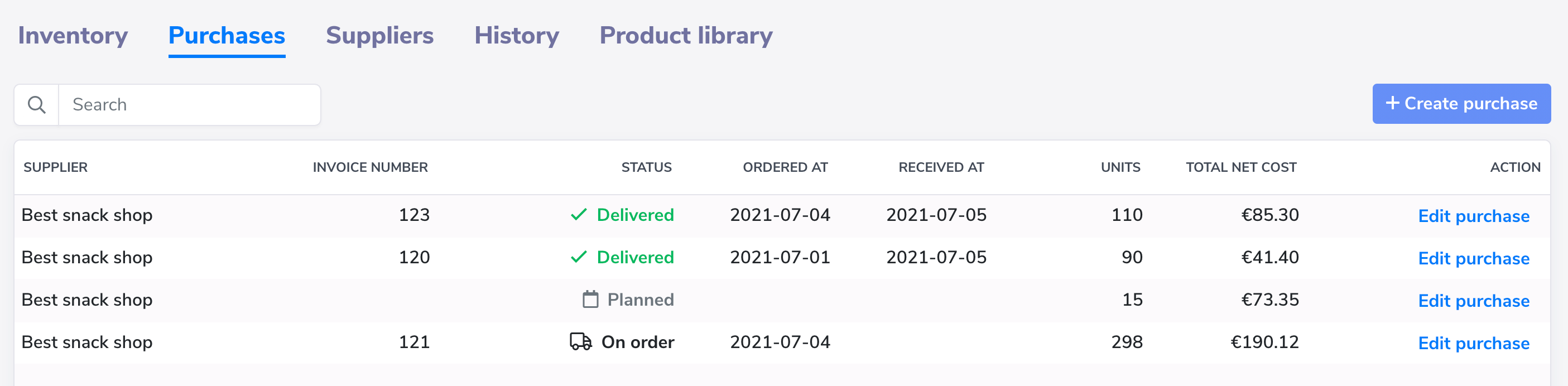

Now in VendingMetrics you can track all purchases and orders to keep all incoming and outgoing transactions in one system. Add scheduled orders, plan new ones, and mark products as delivered to add them automatically to your Inventory.

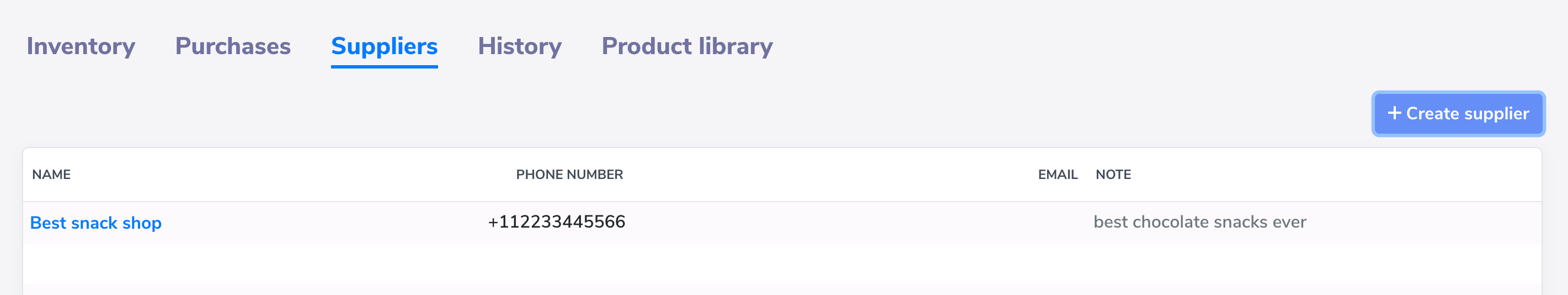

First, add your product suppliers to the list with basic contact information.

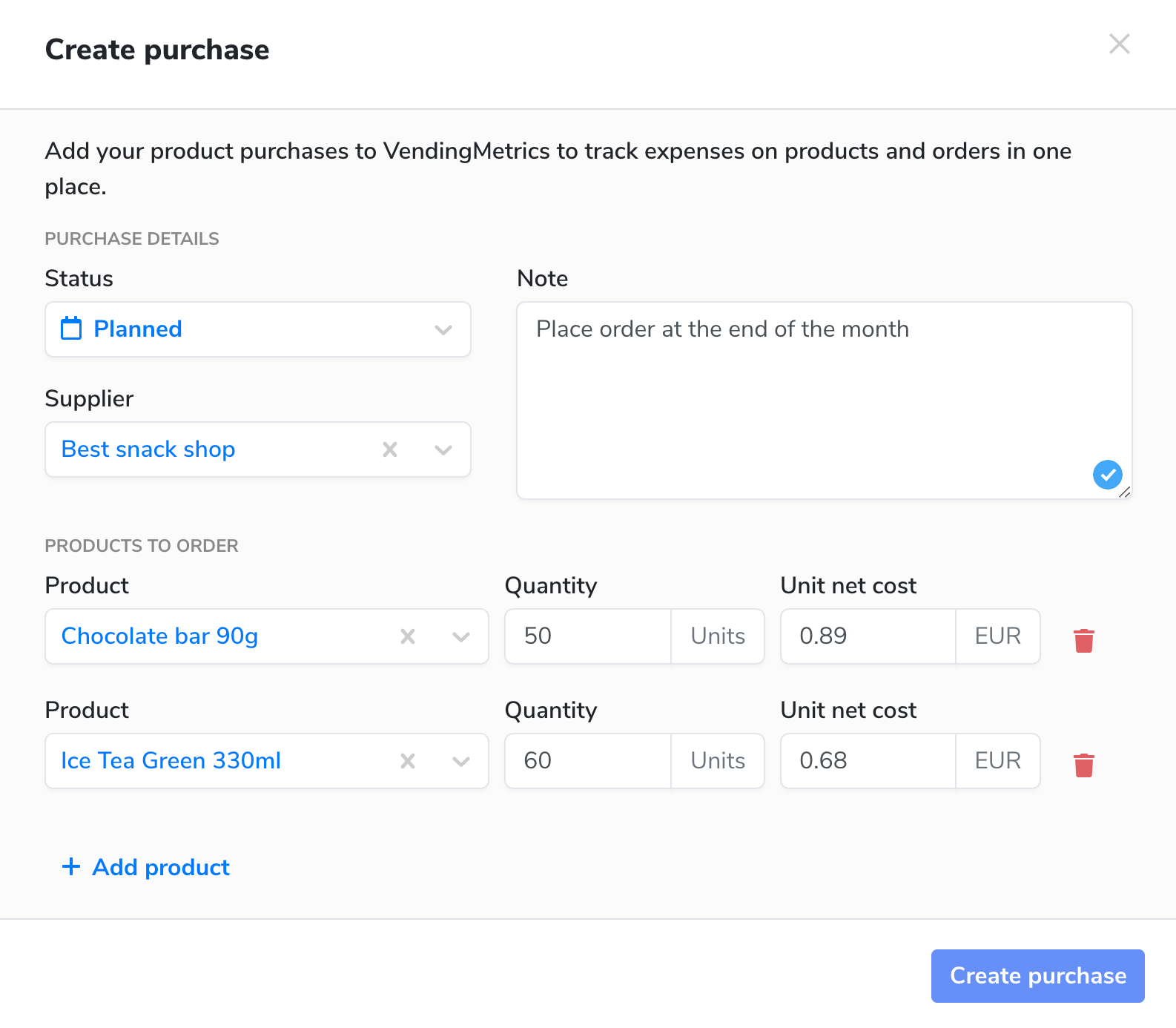

Now, in Purchases tab, you can add new orders by clicking the Create purchase button. See the workflow for creating orders in VendingMetrics system.

- Planned — this is a first step for an order, and it is optional. You can add order with this status as reminder to place order in the future date.

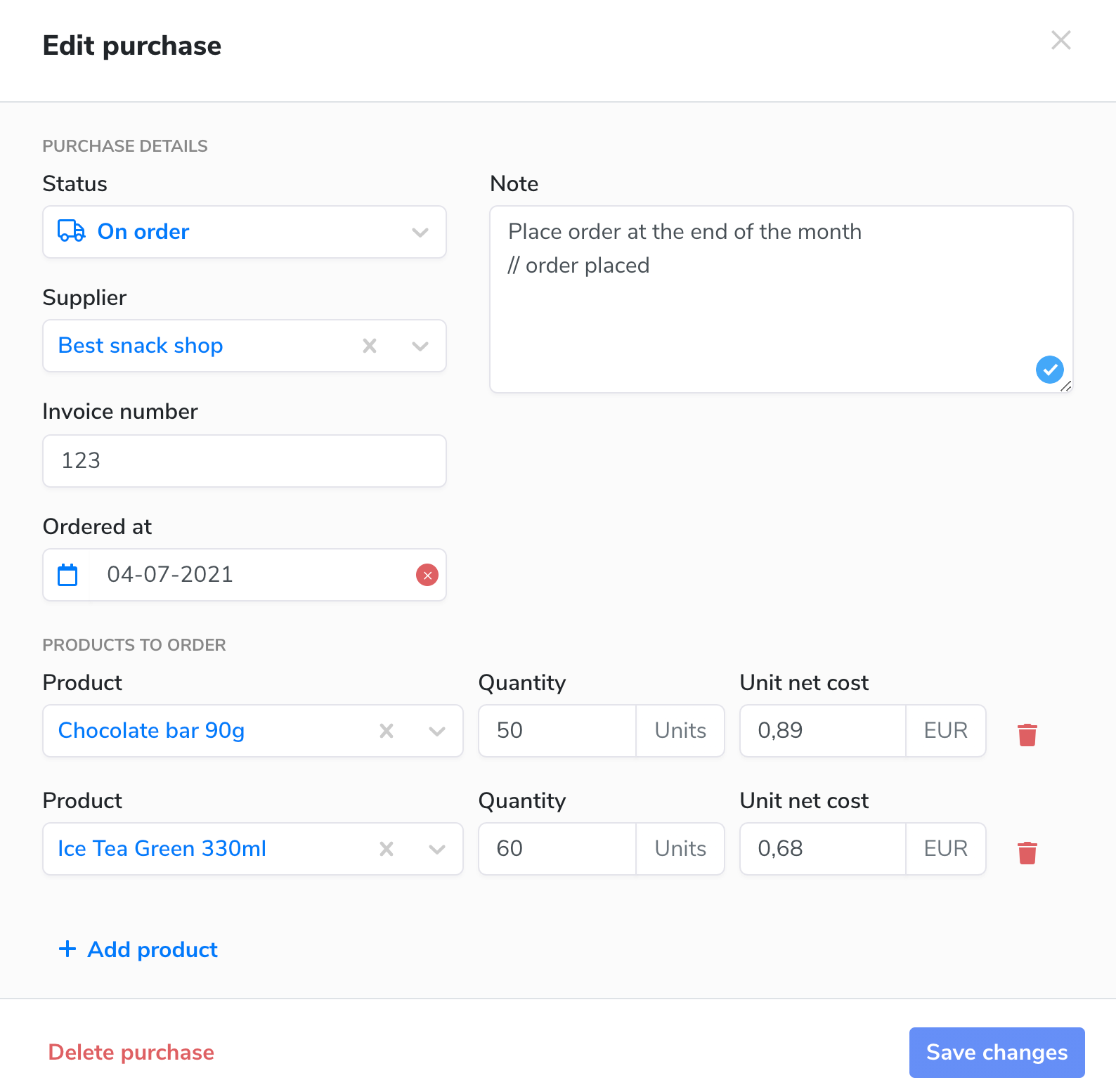

- On Order — when you place an order, you can open the existing planned purchase and change its status to On order. Add the order information, like invoice number and order date.

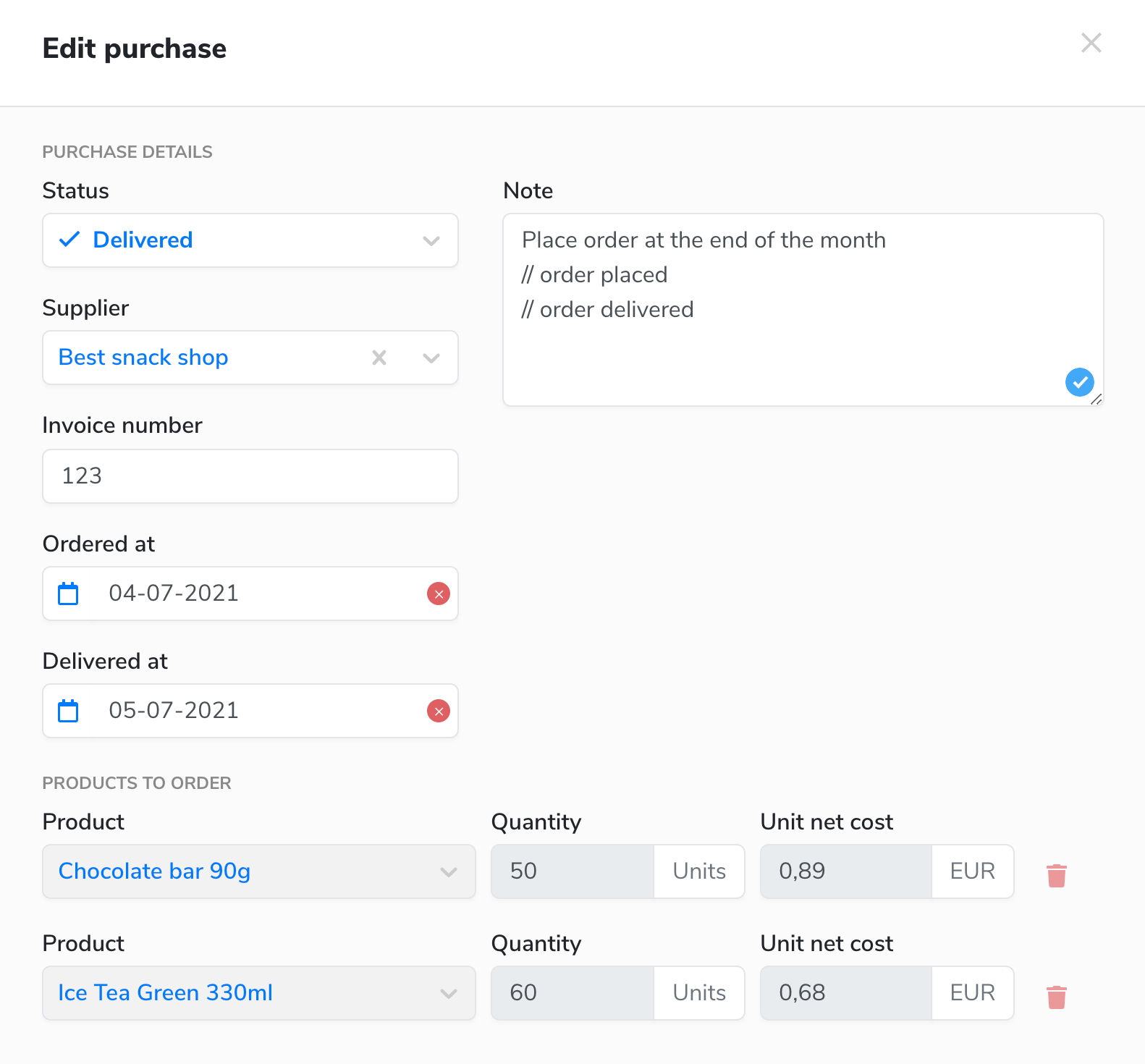

- Delivered — when you receive the order, you can change the purchase status to Delivered. Add the delivery date and save the changes. On that status change, the system will automatically add purchased products to your warehouse inventory.

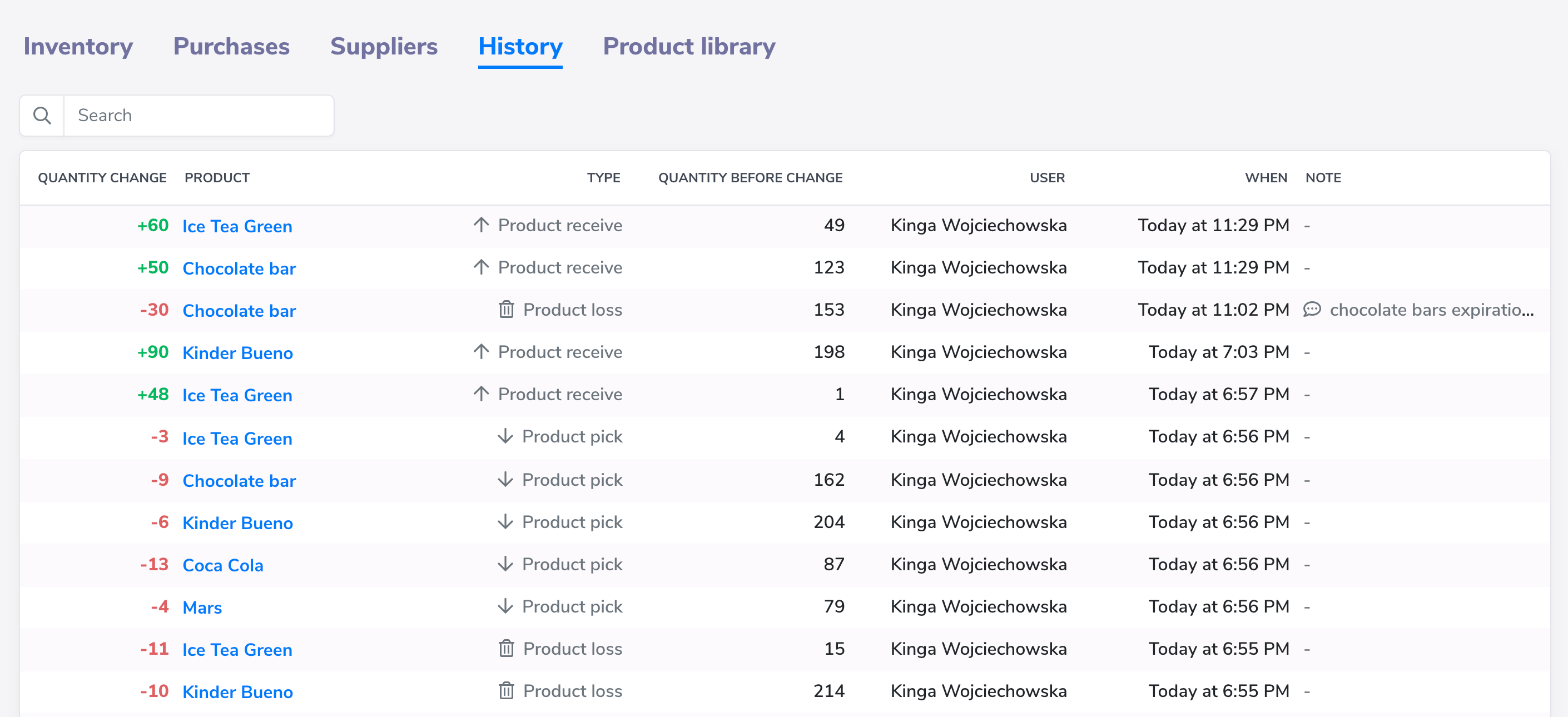

Change history

The history will help you track all changes in your product inventory, it will keep all ins and outs in one place. Thanks to the online inventory management you can say goodbye to papers, excels and sticky notes, and use a clean and simple online list instead.